Resistor

Resistor (Resistor), generally referred to as resistance, generally refers to all electronic or motor accessories used to produce resistance. A resistor operates

according to Ohm's law, and its resistance is defined as the quotient of its voltage divided by its current.

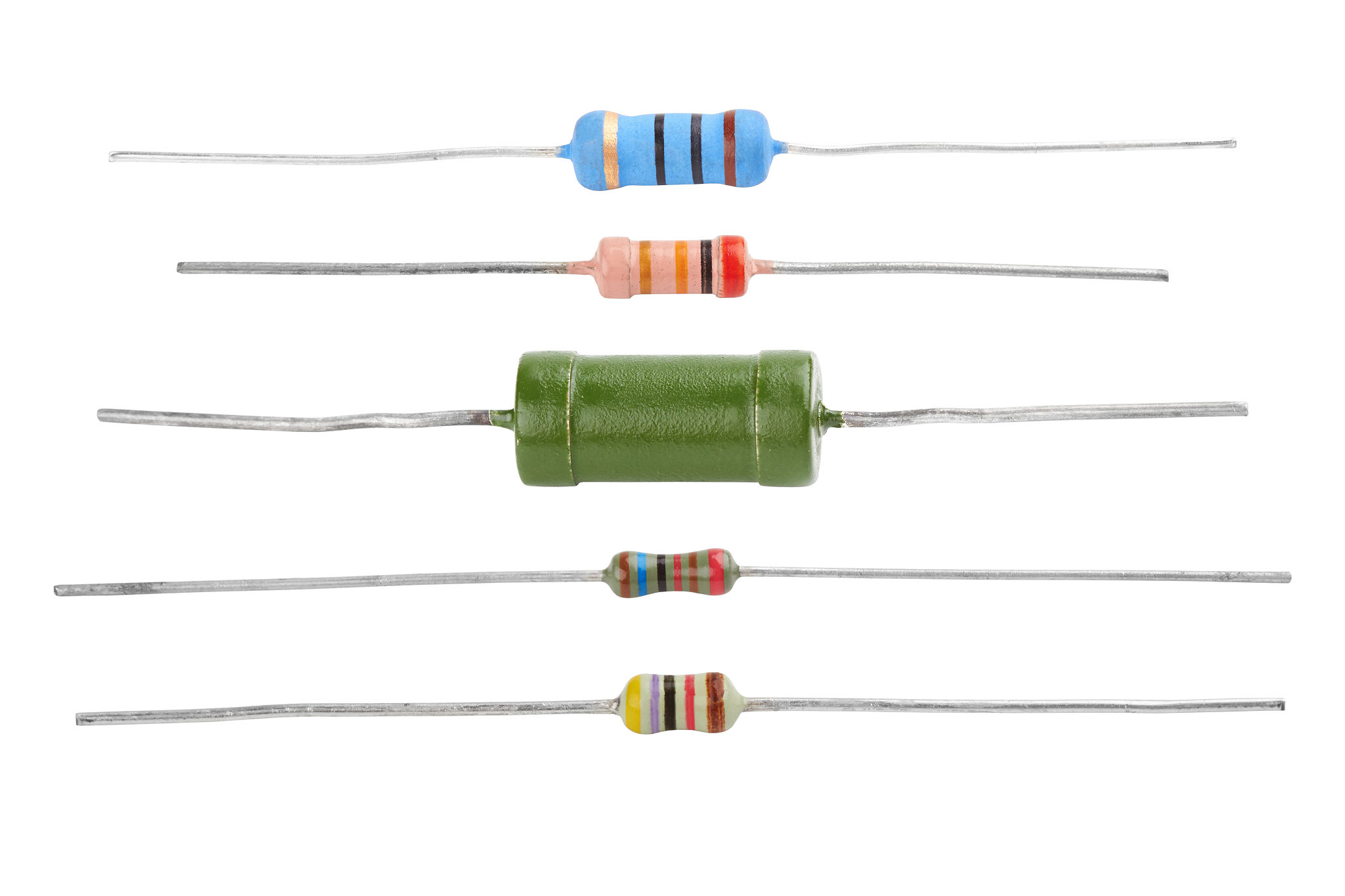

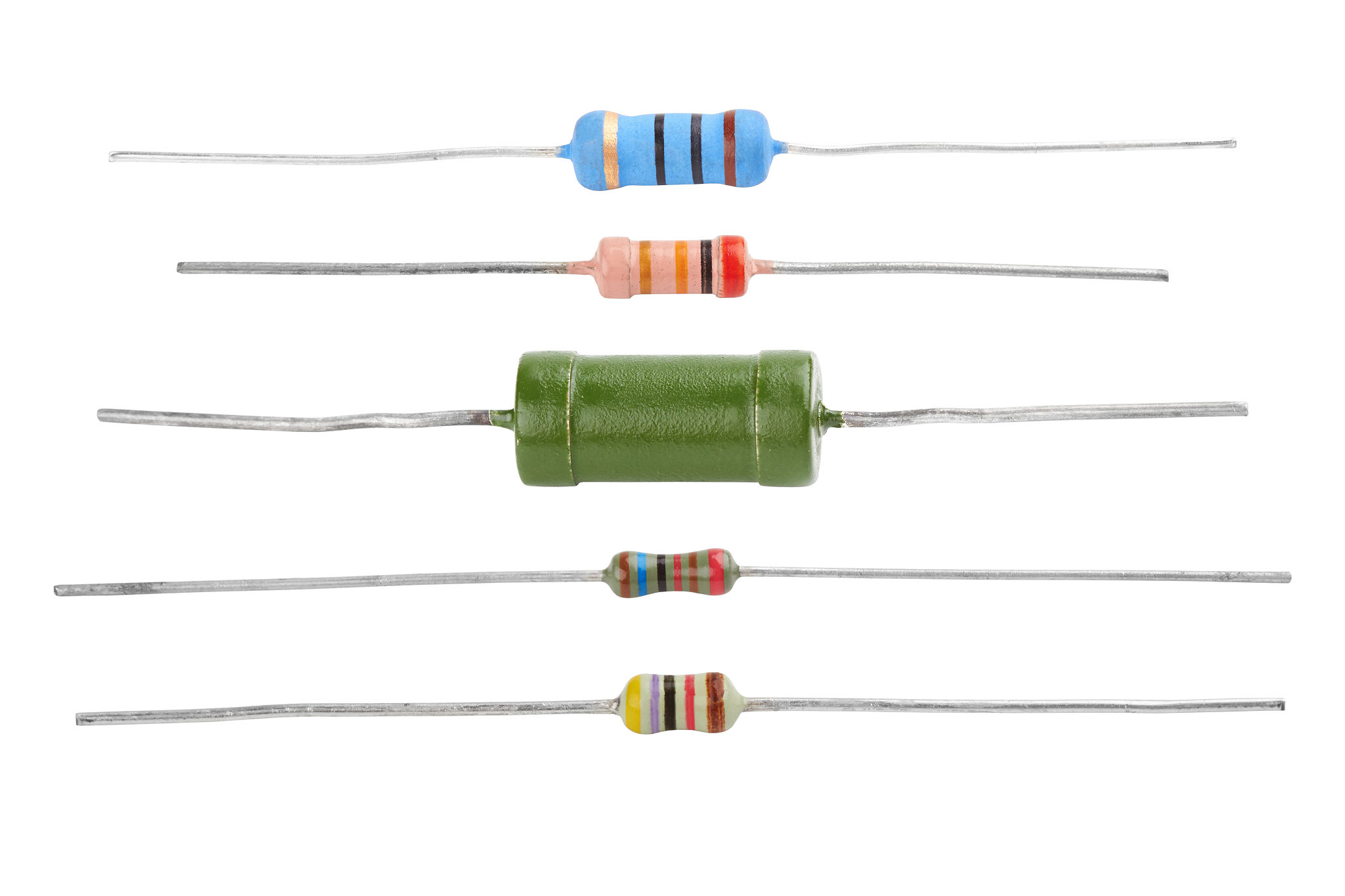

The resistance value marking method of resistance is usually colored ring method, digital method, digital method. The color ring method is more

common on ordinary resistors.

Colour ring method

Color ring method is to use different colors of color scale to represent resistance parameters.

Resistance classification

By resistance characteristics:

Fixed resistance, adjustable resistance, special resistance (sensitive resistance).

Those that cannot be adjusted are called fixed resistance or fixed resistance, and those that can be adjusted are called adjustable resistance. A common

adjustable resistor is a sliding rheostat, such as the radio volume adjustment device is a circular sliding rheostat, mainly used in voltage distribution, called potentiometer.

By manufacturing material:

Carbon film resistor, metal film resistor, wire wound resistor, non-inductive resistor, film resistor, etc.

Thin film resistance

A certain resistivity material is steamed on the surface of the insulating material by evaporation. The main ones are as follows:

Carbon film resistor

Commonly used symbol RT as a sign; For the earliest and most commonly used resistor, the vacuum spraying technology is used to spray a layer of carbon

film on the porcelain rod, and then the outer layer of carbon film is processed and cut into spiral patterns, and the resistance value is determined according

to the number of spiral patterns, the more spiral patterns the larger the resistance value. Finally, the outer layer is coated with epoxy resin seal protection.

Although the resistance error is higher than the metal film resistance, it is cheap because of the price. Carbon film resistors are still widely used in various

products, and are the most basic components of electronic, electrical, equipment and information products.

Metal film resistor

metal film resistor (metal film resistor), commonly used symbol RJ as a symbol; It also uses vacuum spraying technology to spray on the porcelain rod,

but replaces the carbon film with a metal film (such as nickel-chromium), and makes different resistance values on the metal film car, and the porcelain

rod is plated with precious metals at both ends. Although it is more expensive than carbon film resistors, its advantages are low noise, stability, low

temperature impact, and high accuracy. Therefore, it is widely used in advanced audio equipment, computers, meters, defense and space equipment.

Metal oxide film resistor

Some instruments or devices need to be operated in a high-temperature environment for a long time, and the use of ordinary resistors will not maintain its

stability. In this case, a metal oxide film resistor (metal oxide film resistor) can be used, which is formed by burning a layer of metal oxide film on a

porcelain rod with high heat conduction using high temperature combustion technology (a solution of tin and tin compounds is sprayed into a constant

temperature furnace at 500~500 ° C, and coated on a rotating ceramic matrix. The material can also be zinc oxide, etc.), and make different resistance

values on the spiral grain of the metal oxide film car, and then spray non-combustible paint on the outer layer. Its performance is similar to metal film

resistors, but the range of resistance values is narrow. It can still maintain its stability at high temperatures, and its typical characteristics are that the

metal oxide film is more firmly bonded to the ceramic matrix, and the electrical power of the resistance film is also higher. Strong acid and alkali

resistance, salt spray resistance, so it is suitable for working in harsh environments. It also has the advantages of low noise, stability and good high-frequency

characteristics. The symbol RY is commonly used as a symbol.

Synthetic film resistance

The conductive composite suspension is coated on the substrate, so it is also called paint film resistance.

Because its conductive layer presents a granular structure, it has large noise and low accuracy, and it is mainly used to manufacture high voltage,

high resistance, and small resistors.

Winding resistance

Made of high resistance alloy wire wrapped around the insulation skeleton, coated with heat-resistant glaze insulation layer or insulating paint.

Winding resistance has low temperature coefficient, high precision resistance, good stability, heat resistance and corrosion resistance, mainly used for

precision high-power resistance, the disadvantage is poor high-frequency performance and large time constant.

Square wire-wound resistor

Square wire wound resistance (wire wound resistance) is also known as cement electrical group, the use of nickel, chromium, iron resistance larger

alloy resistance wire wound on the non-alkaline heat-resistant porcelain, coupled with heat-resistant, moisture-resistant, non-corrosive material protection,

and then put the wire wound resistance body into the porcelain frame, with special non-combustible heat-resistant cement filling sealed. The difference

in the wire wound resistance of the non-combustible coating is only that the outer coating is changed to silicon Ricon resin or non-combustible coating.

Their advantages are accurate resistance, low noise, good heat dissipation and can withstand very large power consumption, mostly used in the amplifier

power stage part. The disadvantage is that the resistance value is not large, the cost is high, and the inductance is not suitable for use in high-frequency circuits.

Solid core carbon resistor

A solid resistor is made from a mixture of conductive carbon particles, fillers and adhesives. And implant wires during manufacturing. The size of the

resistance value is based on the proportion of toner and the thickness of the carbon rod.

Features: low price, but its resistance error, noise voltage are large, poor stability, less used.

Metallic glass uranium resistor

Metal powder and glass uranium powder are mixed and printed on the substrate by screen printing.

Moisture resistance, high temperature, low temperature coefficient, mainly used in thick film circuit.

Patch resistor SMT

Chip resistance (chip resistance) is a form of metal glass uranium resistance, its resistance body is highly reliable Ruthenium series glass uranium material

through high temperature sintering, characterized by small size, high precision, stability and high frequency performance, suitable for high precision

electronic products in the substrate. The chip rejection is to make a number of the same resistance of the chip resistance into a chip resistance, the

purpose is to effectively limit the number of components, reduce manufacturing costs and reduce the area of the circuit board.

Noninductive resistance

Non-inductive resistors are often used as loads, to absorb unwanted electricity generated during the use of the product, or to buffer, brake, such

resistors are often called JEPSUN brake resistors or Jabison load resistors.

By installation method:

Plug-in resistor, patch resistor.

By function:

Load resistance, sampling resistance, shunt resistance, protection resistance, etc.

|