Product Center

| Fuse

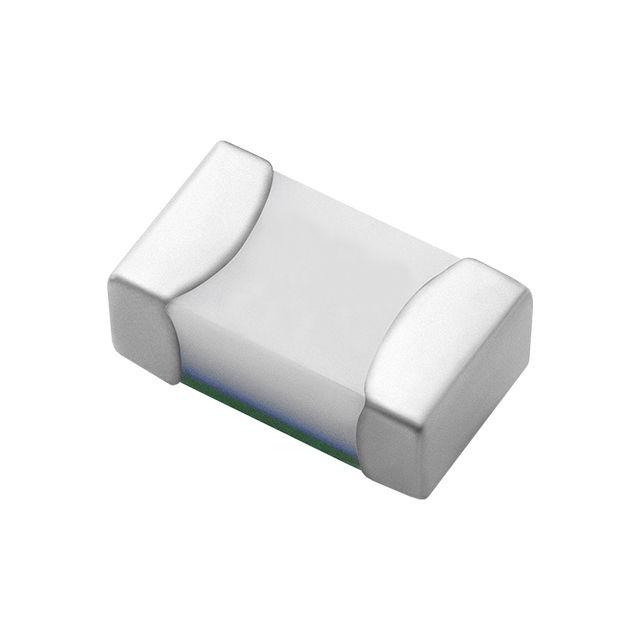

Fuse (fuse) is also known as a current fuse, IEC127 standard defines it as a fuse (fuse-link). It mainly plays an overload protection role. When the fuse is correctly placed constitute Basic composition General fuse is composed of three parts: one is the melt part, it is the core of the fuse, fuse when the role of cutting the current, the same type, the same specification of Arc extinguishing device The fuses used by power circuits and high-power equipment not only have three parts of the general fuse, but also have arc extinguishing devices, because the circuit Fuse breaker In addition, there are some fuses with a fuse indication device, its role is when the fuse action (fuse) after its own appearance changes, easy to be found by sort According to the protection form, it can be divided into: overcurrent protection and overheat protection. The fuse used for overcurrent protection is commonly referred to According to the scope of use, it can be divided into: power fuse, machine tool fuse, electrical instrument fuse (electronic fuse), car fuse. According to the volume, it can be divided into: large, medium, small and micro. According to the rated voltage, it can be divided into: high voltage fuse, According to the breaking capacity, it can be divided into: high and low breaking capacity fuses. According to the shape, it can be divided into: flat tubular fuse (which can be divided into internal welding fuse and external welding fuse), pointed tubular fuse, According to the fusing speed, it can be divided into: ultra-slow fuse (generally represented by TT), slow fuse (generally represented by T), medium speed fuse According to the standard points, it can be divided into: European fuses, American fuses, Japanese fuses. According to the type, it can be divided into: current fuse (patch fuse, micro fuse, insert fuse, tubular fuse), temperature fuse (RH[block type], RP[resistance type], According to the size can be divided into: patch type 0603,0805,1206,1210,1812,2016,2920; 2.4 x 7, non patch Φ Φ 3 x 7, 3.6 x 10 Φ, Φ 4.5 x 15, Φ 5.0 x 20, Self-resetting fuse Low zero power resistance: the self-resetting fuse self-impedance is low, the power loss is small during normal operation, and the surface temperature is low. Fast overcurrent protection: Due to its own material characteristics, the overcurrent state response speed is much faster than other overcurrent protection devices. Self-locking operation: the self-resetting fuse is locked in the high resistance state with a very small current in the overcurrent protection state, and the Automatic reset: The self-resetting fuse resets itself after overcurrent protection (troubleshooting), without disassembling. High current resistance: the self-resetting fuse has excellent high current resistance, and some specifications can withstand 100A current impact. Application: PPTC has a wide range of applications and can be used in various electronic products, communication products, power supplies, etc. |